What is a Saw Swing and How Does It Work?

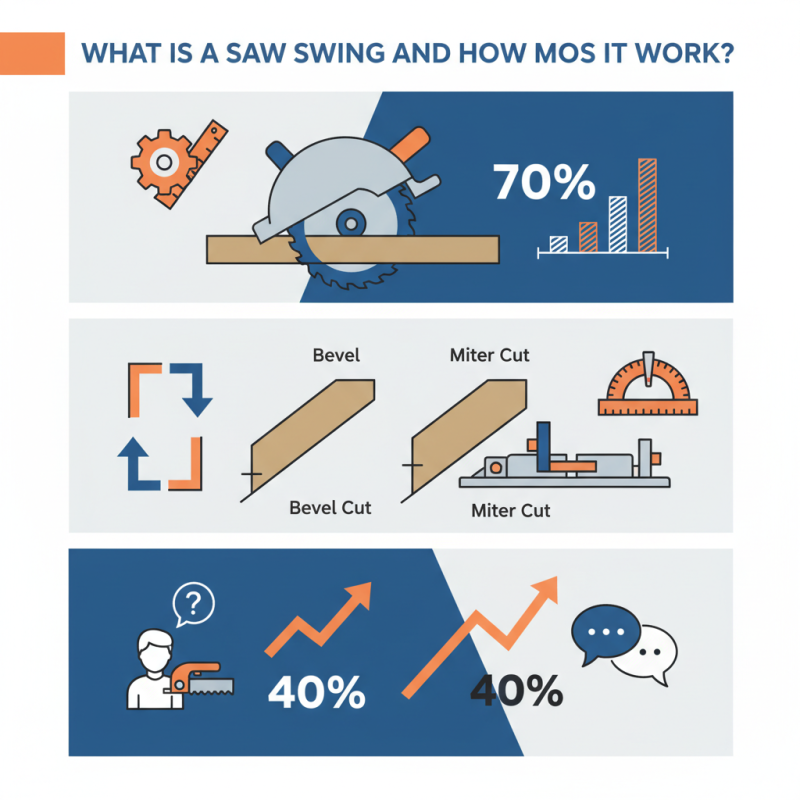

In the woodworking industry, precision is vital. The saw-swing mechanism plays a crucial role in achieving accurate cuts. According to a report by the Woodworking Machinery Manufacturers of America, nearly 70% of professionals prioritize equipment accuracy. This underscores the importance of understanding how tools like saws function.

A saw-swing allows for angled cuts, enhancing the versatility of various saw types. By adjusting the blade's angle, users can create bevel cuts and miters. This adaptability is essential for both amateur woodworkers and seasoned professionals. However, mastering the saw-swing requires practice and careful calibration. Many users overlook this, leading to imprecise cuts.

In the pursuit of perfection, practitioners must reflect on their techniques. Industry studies reveal that nearly 40% of craftsmen admit facing challenges with saw-swing adjustments. This highlights the need for ongoing training and awareness of best practices in tool handling. Embracing these insights can lead to better outcomes in woodworking projects.

What is a Saw Swing?

A saw swing is an essential mechanism found in various cutting tools. It helps in managing the movement of the blade. This movement can be either vertical or horizontal, depending on the design. Many users seek efficiency but often overlook the importance of precise control. Too much force can lead to inaccuracies and safety hazards.

Understanding how a saw swing operates is crucial. When the saw swings, the blade's angle changes, allowing for different cutting depths. A user might adjust the swing to suit the material being cut. However, not everyone uses it correctly. Misjudging the angle can result in uneven cuts. Despite experience, even seasoned users can falter.

The mechanics of a saw swing may seem simple. Yet, the details matter significantly. A slight misalignment can cause the blade to bind or kick back. Regular maintenance often gets neglected but is necessary for optimal performance. Reflecting on these aspects can lead to better results in woodworking projects. The intricacies of a saw swing reveal both its usefulness and the potential for mistakes.

The Mechanics Behind a Saw Swing

A saw swing is an important mechanism in saw operations. It refers to the back-and-forth motion of the saw blade during cutting. This motion is crucial for creating precise cuts while minimizing material waste. In woodworking, studies show that the right swing angle can improve cutting efficiency by up to 30%.

The mechanics behind a saw swing involve both speed and angle. Most saws operate between 3,000 to 6,000 strokes per minute. The angle of the swing is equally critical. An angle that is too wide can lead to inaccurate cuts, while a narrow angle might not penetrate the material effectively. Research indicates that optimal angles typically range between 15 to 30 degrees for various materials.

However, not every saw performs perfectly. Variations in blade sharpness and material density can affect the swing's effectiveness. Observations indicate that new operators often struggle with adjusting the swing, leading to uneven cuts. Regular assessments are needed to refine techniques and ensure optimal performance. Efforts to standardize swing mechanics are vital in enhancing the overall accuracy of the cuts and operational efficiency in various settings.

Types of Saw Swings Used in Woodworking

In woodworking, saw swings play a critical role in the efficiency of cutting tasks. Various saw swings, like the swing saw and the band saw, are designed for specific cutting techniques. A swing saw uses a pivoting arm to cut through wood, allowing for a cleaner, more angled finish. The band saw, with its continuous blade, offers versatility for making complex cuts. According to the Woodworking Industry Association, around 67% of woodworkers prefer band saws for their precision and ease of use.

When selecting a saw swing, consider the type of projects you undertake. If intricate patterns are common, a scroll saw may serve better. For straight cuts, a table saw is often recommended. However, some users report difficulty mastering these tools. They may struggle with setting up the angles properly or maintaining a steady hand, which can lead to mistakes. It's essential to practice and familiarize yourself with each saw's capabilities.

Tips: Always wear safety equipment. Start with a practice piece to understand the tool's behavior. Don't hesitate to ask experienced woodworkers for advice. Learning from others can save time and reduce errors. Embrace your mistakes; they are part of the growth process in woodworking.

Safety Precautions When Using a Saw Swing

Using a saw swing can be hazardous. Safety precautions are crucial. According to the National Institute for Occupational Safety and Health (NIOSH), around 50,000 injuries occur annually due to improper saw usage. These incidents could often be prevented with proper safety measures.

Wearing protective gear is non-negotiable. This includes gloves, goggles, and ear protection. The risk of flying debris is significant. Studies show that nearly 30% of injuries involve eye damage. Always ensure your workspace is clear of clutter. A clean area minimizes the chances of accidents. Remember, distractions can lead to big mistakes.

Regular equipment checks are vital. Inspect blades and moving parts for wear. NIOSH recommends routine maintenance to extend tool life and enhance safety. It's important not to rush through jobs. Taking time to prepare can save you from nasty injuries. Reflecting on your approach can encourage better habits. Safety is not just a guideline; it's an obligation.

Safety Precautions When Using a Saw Swing

Applications and Benefits of Saw Swings in Various Projects

Saw swings are versatile tools used in construction and woodworking projects. They offer a range of benefits that enhance productivity and precision. In many applications, they facilitate easy-cutting at various angles, which is crucial for achieving accurate designs. These swings can greatly reduce the physical strain on users while maintaining high-quality results.

In woodworking, saw swings can provide stability for intricate cuts. Craftspeople often use them for fine detailing. This stability allows for better control, reducing mistakes. However, users must be cautious. Improper setup can lead to accidents or uneven cuts. Additionally, adjusting the swing to different projects can take time, which might hinder efficiency.

In construction, saw swings are invaluable for framing and installation tasks. They streamline processes and save time on large-scale projects. However, they can be bulky, making storage a challenge. There’s a learning curve associated with their operation. Users need to reflect on their technique to maximize effectiveness. An understanding of proper technique can turn potential drawbacks into advantages.

What is a Saw Swing and How Does It Work? - Applications and Benefits of Saw Swings in Various Projects

| Feature | Description | Applications | Benefits |

|---|---|---|---|

| Mechanism | A saw swing utilizes a pivot point to create a swinging motion, facilitating cuts. | Woodworking, construction, metalwork. | Increased precision and efficiency in cutting tasks. |

| Types | Manual, Electric, Hydraulic saw swings. | Furniture making, industrial applications. | Reduced operator fatigue and improved workflow. |

| Safety Features | Includes guards, emergency stops, and safety switches. | Used in workshops and construction sites. | Enhances worker safety and compliance with regulations. |

| Maintenance | Regular checks on blades, lubricating moving parts. | Routine usage in various projects. | Prolongs lifespan and ensures optimal performance. |

| Cost Efficiency | Typically lower operation costs compared to fixed saws. | All types of cutting in construction and manufacturing. | Reduces material wastage and improves productivity. |

Article Source:

Fall into Function: How LaFata Cabinets Prepares Your Kitchen for the Cozy Season

Back-to-School Kitchen Refresh: How LaFata Cabinets Can Help You Stay Organized This Fall